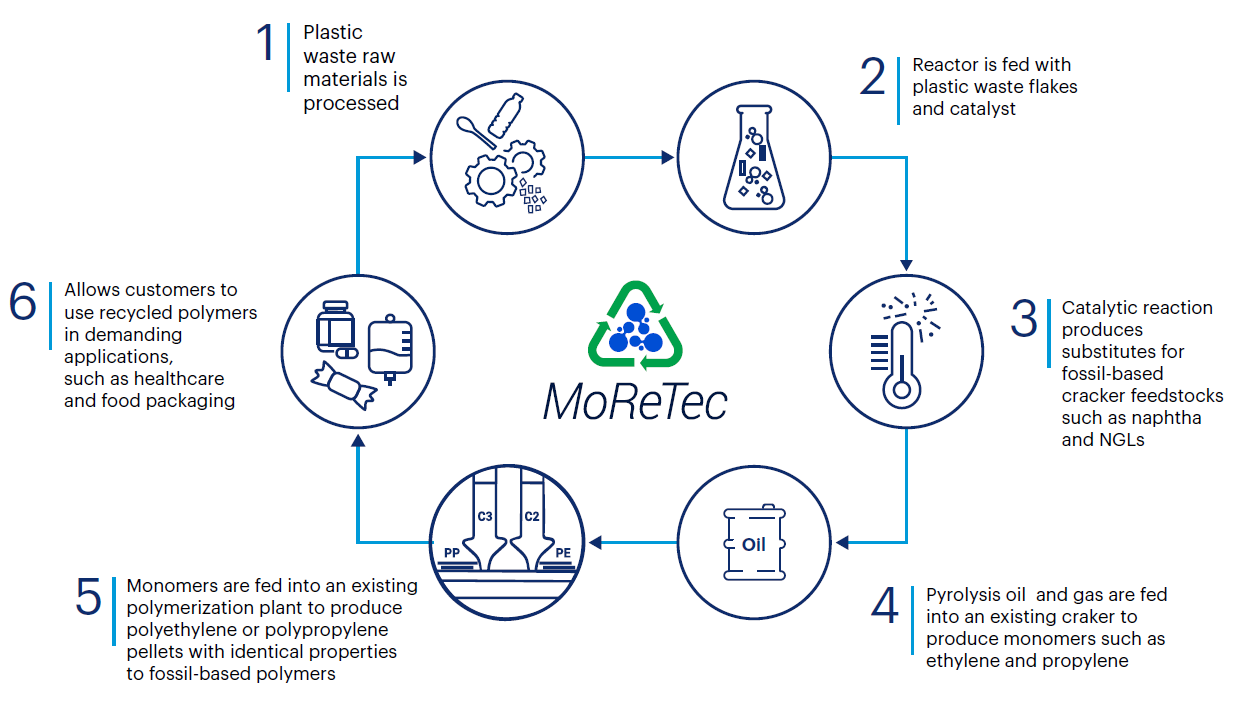

With its proprietary MoReTec advanced recycling technology, LyondellBasell (LYB) aims to return post-consumer plastic waste to its molecular form. The pyrolysis oil and pyrolysis gas from the process can be used as a feedstock for new plastic materials that offer expanded applications, including medical and food packaging.

MoReTec

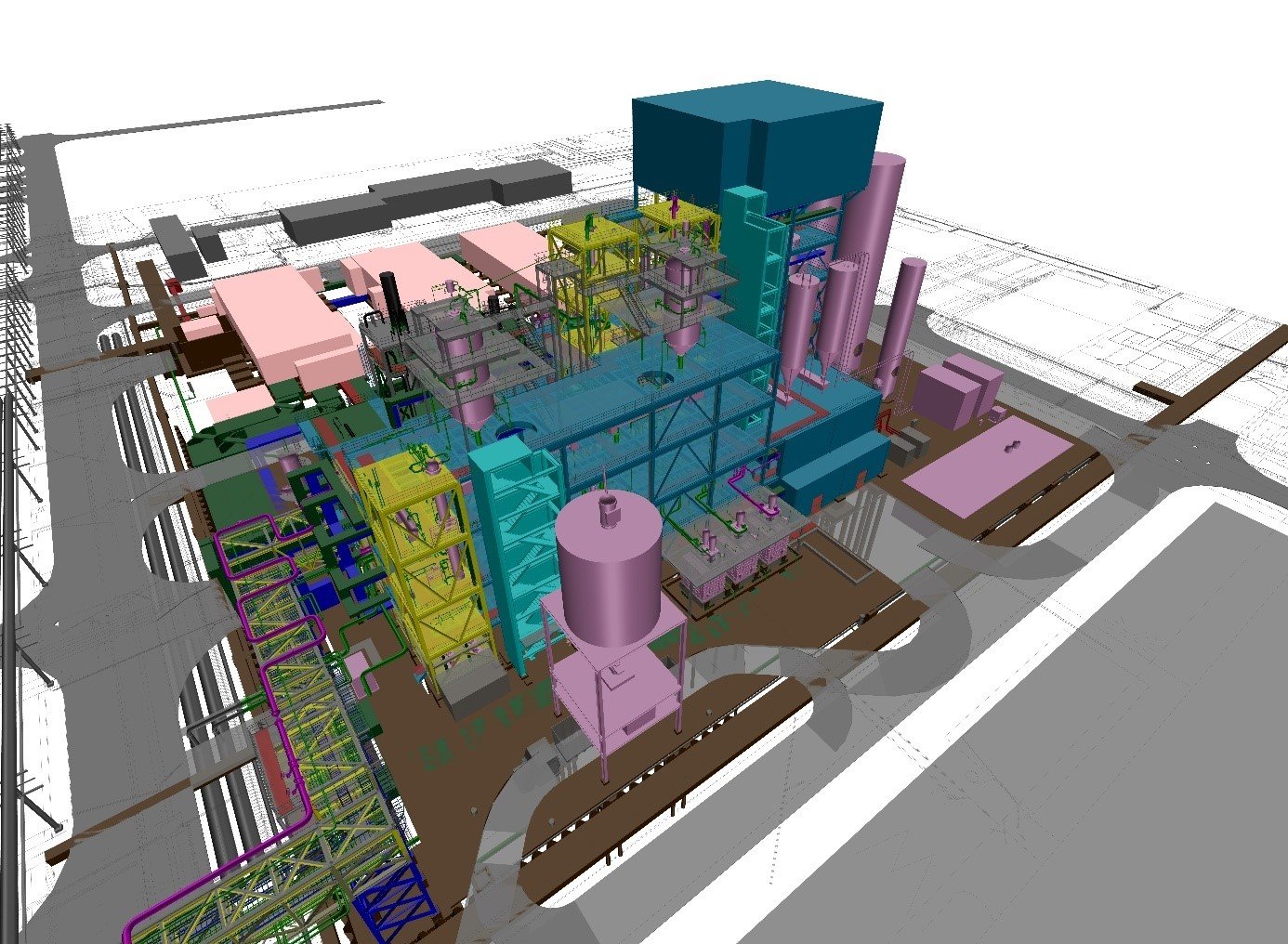

LYB is building the first of its kind commercial scale MoReTec plant in Wesseling, Germany. This represents the next step towards addressing the challenge of hard-to-recycle plastics at scale. The investment will provide us with valuable operating experience and additional technological know-how needed to scale-up and fully commercialize our MoReTec technology.

About the MoReTec-1 Project

In 2023, we made the final investment decision to build MoReTec–1, a first-of-its-kind commercial-scale advanced recycling plant that will use our proprietary MoReTec technology to convert post-consumer plastic waste into feedstock for the production of new polymers. The new plant will be located at our site in Wesseling, Germany, and is expected to have an annual capacity of 50,000 metric tons per year. It is designed to recycle the amount of plastic packaging waste generated by over 1.2 million German citizens per year.

Source One Plastics, a joint venture of LYB and 23 Oaks Investments formed in October 2022, will supply the majority of the processed plastic waste feedstock for MoReTec–1 from its new sorting and recycling facility in Eicklingen, Germany. The Source One plant, which started up in February 2024, processes difficult-to-recycle post-consumer plastic waste, such as mixed plastic packaging and flexible polyolefins materials that would otherwise be sent mostly to incineration. It uses an innovative dry processing method to reduce energy consumption by up to 30% compared to conventional technologies. The system is designed to minimize the occurrence of fine plastic dust and its release into the environment. The plant will be powered by locally generated renewable energy.

The advanced recycled feedstock produced by the MoReTec facility will be used for the production of polymers sold by LYB under the CirculenRevive brand for use in a wide range of applications, including medical and food packaging.

Construction of MoReTec–1 is expected to be completed by the end of 2025.

LYB has been selected to receive a €40 million grant from the European Union (EU) Innovation Fund to support our MoReTec–1 plant in Wesseling, Germany. This plant is one of the 41 projects selected in the EU Innovation Fund ‘Third Call for Large Scale Projects.’ The EU is committing EUR 3.6 billion as part of its efforts to fund innovative clean-tech projects to support decarbonization. We are honored that our advanced recycling technology has been recognized by the EU for its promise to address plastic waste and contribute to a circular economy

Funded by the European Union. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or the European Climate, Infrastructure and Environment Executive Agency (CINEA). Neither the European Union nor the granting authority can be held responsible for them.

The MoReTec Technology

LyondellBasell has been conducting base research to develop its own advanced (molecular) recycling technology, MoReTec, since 2018. In 2020, LyondellBasell began operating a semi-industrial scale MoReTec pilot plant in Ferrara, Italy. The MoReTec technology complements mechanical recycling by converting flexible packaging and mixed plastic waste, that today end up in landfill, incineration or the environment, into pyrolysis oil and pyrolysis gas.

The MoReTec technology produces pyrolysis oil and pyrolysis gas. Pyrolysis oil is a substitute for fossil-based materials used in polymer production. In competing technologies, pyrolysis gas streams are typically consumed as a fuel. However, the MoReTec technology enables the pyrolysis gas to be recovered as well, avoiding emissions associated with using the pyrolysis gas as a fuel, while also contributing to the production of polymer and replacing fossil-based feedstocks. These polymers are used for applications that require high purity, such as food contact materials.

The MoReTec technology offers several significant advantages including:

-

The innovative process maximizes the plastic recycling rate while minimizing fuels.

-

Lower process temperatures and high energy efficiency reduce energy consumption and associated greenhouse gas emissions.

-

The electrical heating design enables the process to be powered by renewable electricity.

-

The MoReTec process can be scaled up, further increasing efficiencies.

These differentiating advantages provide a carbon footprint advantage as well. The recovery of pyrolysis gas as feedstock, lower energy demand, electrical heating design, replacement of fossil-feedstocks, and recovery of waste plastic from incineration or landfill result in a lower carbon footprint compared with fossil-based processes.